“Green” is of fashion and no marketing and public relation department of a company nowadays can effort to stay aside of this mainstream. The question, however, always is to what extent endeavours are substantial or not much more than just image painting. Also those who honestly want to contribute to port sustainability are sometimes heading into the wrong direction, simply because there are so many concepts on the market and selecting an effective one requires very specific knowledge.

The European Commission strategies in general aim at sustainable mobility of passengers and goods and specifically at sustainable ports also mirrored by the work programmes of the research frameworks. The GREEN EFFORTS [1] project, co-funded by the European Commission, after 30 months was concluded end of June this year. There were comprehensive terms of reference which can be simplified by stating “GREEN EFFORTS aimed at making terminals and ports a better place to work and to live with” as carbon footprint mitigation was the principal objective specified by the European Commission.

The project was a true challenge for mainly two reasons:

- Port sustainability was and is an objective well supported by policy makers, the industry, administrations and the public but there is quite some fuzziness how this could be achieved in detail.

- There is a tremendous lack of process information, making it very difficult to compare, calculate and to estimate, a very uncomfortable situation for scientific work.

Frequently sustainability is understood an altruistic goal, easy to communicate but difficult to realize within the industry. The majority of port and terminal managers personally is supporting the idea of greener ports, however, when it comes to investments, they are afraid of the shareholders.

GREEN EFFORTS therefore translated reduction of emissions into reduction of energy consumption and hence costs, which for ports and terminals is true. Thus the subject became attractive for the port industry.

With reference to energy consumption data the project, however, was very lucky to find industrial partners to cooperate, not only in Europe but especially in South America, where energy efficiency seems to cause more headaches than in Europe. At a later project stage United Nations Economic Commission for Latin America and the Caribbean (UN ECLAC) in Santiago de Chile coordinated the support resulting in a large collection of consumption data [2].

As the focus of interests of ports and terminals, depending on the port model, usually is different, also involvement of ports was searched for and mainly found in Singapore, Los Angeles and the European Ports of Antwerp and Hamburg. The RoRo Port of Trelleborg and the inland navigation Port of Riesa (upper river Elbe) as consortium partners represented their special operational profile. However the majority of the project work aimed at container terminals as these are the biggest representatives of the industry with the highest energy consumption.

According to costs associated to recommended measurements, the project rationale was a short, medium and long-term approach to achieve improved energy-efficiency by:

- operational and attitude (staff) measurements, achievable by no or low costs

- technical modifications of existing handling equipment and systems, requiring some investments

- innovative solutions, the most costly but also the most effective measure.

Port of Hamburg. Hinterland Connections. (Photo: Michael Zapf)

Knowing Energy Consumption

As you can only manage what you can measure, the most important first step to save energy is to know the consumption in great detail. Surprisingly this is frequently not the case. The reason might be that until recently energy consumption was not in the focus of the management but now, by continuously increasing energy costs, gains importance. To track energy consumption accurately requires already some investment to install meters and recording systems for electric power and fuel.

Correlation between processes, equipment used and energy consumption allows then to focus measures on the most promising areas.

Regenerative Energies

It cannot be expected that an industrial site as a port encompassing terminals and logistics services is prepared to act as a test-bed for the wide scope of ways to reduce emissions, without knowing the results. The way to mitigate the carbon footprint is either by reducing the energy consumption or by exploiting low or even zero emission energies. Regenerative energies are therefore an attractive option. GREEN EFFORTS grouped these according to technical feasibility, maturity and efficiency.

- Photovoltaic [3]

- mature and many years of experience

- easy to install and to maintain

- dual-purpose prone, mainly in combination with all kind of roofs

- efficient, however, depending on sun shine hours

- short-term estimation (1 to 3 days) of expected output sufficient reliable, hence easy to become integrated into the local energy management

- alternatives of panels according to conditions and environment

- recently introduced new development regarding material and electric functionality

- Wind [4]

- mature and many years of experience

- short-term estimation (1 to 3 days) of expected output sufficient reliable

- high electrical output possible but volatility requires intelligent supply and storage management

- adequate for coastal regions with more wind at higher energy density than in inland areas

- cumbersome and time-consuming approval procedure in most European countries

- high installation costs

- some people find the wind turbines disturbing

- problem of possible icing solved

- special maintenance required

- Biogas [5]

- mature and many years of experience

- small scale plants not efficient but large scale plants require high amount of bio-material which may cause ethic discussions if not restricted to garbage and rural waste

- operation requires expertise not available on terminals

- an adequate solution for larger ports in combination with larger amounts of ships garbage

- Geothermal energy [6]

- Mature and many years of experience

- Efficiency depending on geographical site (the geothermal share in total energy consumption of Iceland is about 30% compared to less than 2% in Italy)

- Near-surface systems require large areas for significant energy production whereas deep systems (4.000 to 7.000 m) require very high drilling costs.

Other regenerative energy sources are either not sufficiently mature or require too much effort for a port or a terminal. Low emission fuels as hydrogen (e.g. from “(wind)power to gas”), methanol and ethanol (e.g. from biomass) can become considered as regenerative when being produced accordingly but have a very restricted availability. Only the non-regenerative fossil fuel methane as liquefied natural gas (LNG) or as compressed natural gas (CNG) appears a promising alternative and is currently strongly supported by European policy. Methane produces considerably lower emissions than other fossil fuels but as the global warming potential of methane is about 23 times that of carbon dioxide a 100% combustion is essential which usually is only possible in gas turbines and not in piston motors.

The above shown list speaks for itself: photovoltaic in areas with sufficient sunshine hours is a must, wind generators are recommended but there are doubts that it is an appropriate terminal business, therefore the ports should deal with it as operation and maintenance requires some efforts. Economies of scale is an issue by operating a larger number of wind turbines in the same area and not just one on a terminal. Biogas can be considered once conditions and circumstances allow for a convincing business model.

Reduction of Energy Consumption on Terminals

Main energy consumers of container terminals are the container handling equipment, the reefers (depending on the cargo split between chilled and deep frozen commodities) and the yard lighting. Priority of tackling energy consumption should always follow the realistically feasible potential of reduction and the cost-benefit ratio. Adjustment of power units to real needs, hybridization and electrification have recently well been covered by various publications.

LED (light emitting diodes)

Lighting in container terminals and port areas is a significant opportunity to improve the energy efficiency. The change from fluorescent light tubes or High Pressure Sodium (HPS) lights to LEDs typically reduces the consumption by about 50%. LEDs can be used in practically all areas, such as buildings (offices, storage, workshops, cafeterias, …), container/goods moving equipment (cranes, straddle carriers, …) and yard lighting. Besides increased energy efficiency there are other significant advantages like higher life time, lower maintenance cost, intelligent controllability, adaptation of spatial emission and light quality. The most significant disadvantage of LEDs is the fact that they are still significantly more expensive than other light sources. However, due to the lower energy consumption, the total cost of ownership over the lifetime is lower than for all other light sources [7]. However, a lifetime of about 100.000 hours, as claimed by the manufacturers, should not be taken for granted as the light output diminishes over time. For lifetime cost calculation about 40.000 hours seems to be more realistic but this needs to be proven by experience.

There are already many industrial LED installations with generally positive feedback. The sometimes reported disadvantages as color temperature and occasional stroboscopic effects can be avoided by appropriate selection of light panels. As LEDs result in less diffusion than HPS there is less “light pollution”, frequently claimed by residents living in a port vicinity.

Energy Management

Conventional supply of electrical power for industrial use is provided via a public grid to satisfy the demands of the customers (consumers) based on certain tariff conditions. Industrial power supply tariffs usually consist of a basic charge, a consumption charge and a peak surcharge. The consumption charge commonly is based on a defined power factor. The power factor provides the ratio between the active power (to do the work) and the apparent power. The difference, the reactive power, in an AC-system is needed to support the power transfer via the network. Once the power factor is lower than as to the tariff conditions, the customer pays for energy which does not do any work. The application of the peak surcharge is also specified in the tariff and usually based on 15 minutes-measurements of the total power supply. The peak surcharge commonly means an increase in consumptions charge by a specified percentage.

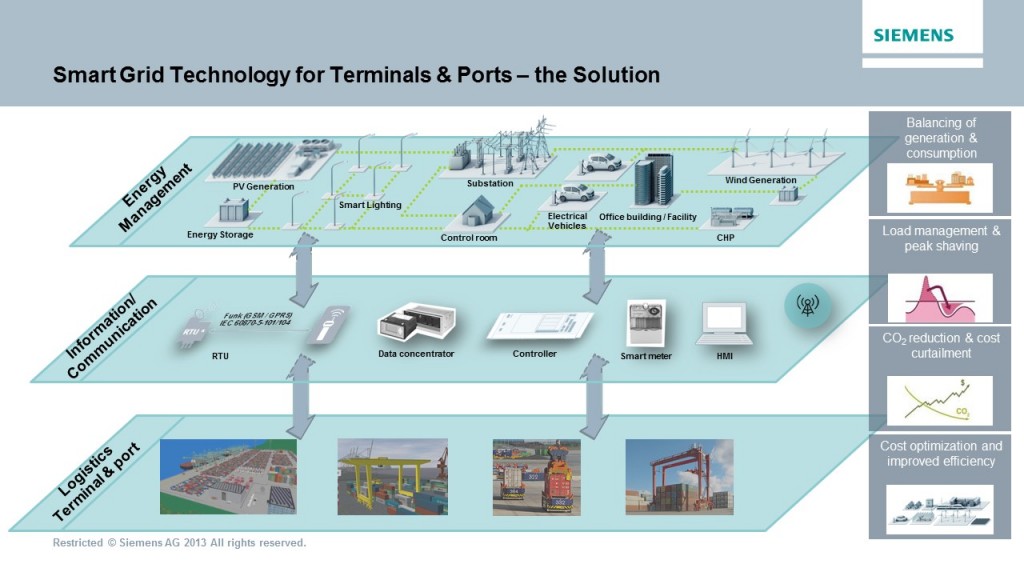

Intelligent matching of demand and supply of electrical power requires a communication network to exchange digital information parallel to the power network controlling meter data management, condition monitoring and automation, then becoming a smart grid [8].

Terminal smart grid applications aim at the management of:

- Selection of energy supply alternatives from onsite energy production and storage, conventional and regenerative energy supply via the public grid and to benefit from low tariff periods

- Energy storage

- Load shedding, i.e. avoidance of consumption peaks

- Real-time power factor correction (fast reactive power control).

In practical terms and in respect of mature technologies the following applications are promising to consider technical modifications and investments on terminals:

- Usage of electrical power once it is clean and cheap (“cc-power”). This is feasible in all regions where the percentage of regenerative energies, mostly from wind generators, is high. In periods of e.g. high amount of wind energy, which often coincides with periods of low consumption, the grid provider cannot sell the energy and is willing to provide it at lower costs. However, the terminals might also not be able to use this attractive energy, resulting in a low carbon footprint and at low costs, only when energy storages can bridge the time gap between supply and demand. Batteries of sufficient capacity and operational profiles are still expensive but there are other opportunities on a terminal to store the energy for later use, i.e. by battery-driven vehicles and equipment. E.g. a container terminal using electrical automated guided vehicles (AGV) provides a large storage capacity by the AGV-batteries. An agreed smart grid function between the grid provider and the terminal then is to automatically recharge the batteries during periods of availability of clean and cheap energy.

- Power balancing, i.e. peak shaving and “valley filling” to flatten the demand curve and hence avoid peak surcharges by managing energy consumption, where operational time-shifts are possible, and by energy storage [9]. A container terminal with a larger number of reefers containing deep frozen cargo may e.g. integrate the reefer monitoring system into the local smart grid to control compressors and apply “advanced cooling”, i.e. lowering the setpoint temperature once clean and cheap energy is available and to not cool during other periods. This is usually not applicable for sensitive chilled cargo.

- Reactive power compensation via power conversion devices to improve the power factor [10].

Smart Grid for Terminals and Port. (GREEN EFFORTS/SIEMENS)

Battery storage

Is imperative for a local smart grid (microgrid) to balance energy demand and supply and to flatten the peak curve. The batteries must allow for a high number of cycles, provide high cycle stability and high power output on short duration to ensure voltage quality (e.g. compensation of reactive power) and longer storage duration for time shifting of consumptions. Such batteries, redox flow batteries, are now available and have recently proven their industrial viability. For industrial use vanadium redox flow batteries with a capacity up to 1600 kWh and a power rating of 200 kW are currently available. By connecting several units the storage system can be scaled to the required capacity.

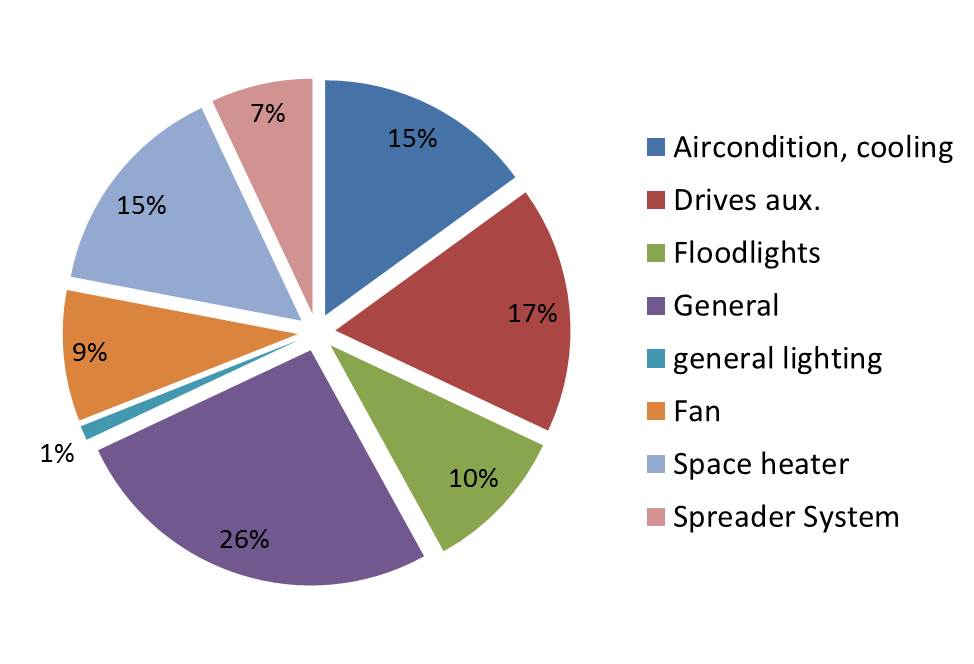

Ship-to-Shore Cranes

Standby consumption of ship-to-shore container cranes seems to be an often underestimated issue. The variations found in standby consumption are very wide, mostly depending on the lighting system connected to the crane. The figure below shows a good example of the contribution of the different consumption sinks [11].

STS Container Crane – Standby Consumption Sinks. Example. (Uwe Pietryga, Kocks Crane International)

After knowing the actual distribution of standby consumption measures can be taken to reduce it by:

- adapting the lighting to real needs and by replacing high pressure halogen or sodium floodlights by LEDs including automated switch off devices

- replacing hydraulic spreaders by electric spreaders, power switched off when not in operation, not only reducing the power consumption significantly but also avoiding oil leaks and hence cleaning necessities

- adaptive air condition, fans and heating, just meeting essential needs

- measuring consumption of other auxiliary systems including IT to reduce it wherever it is technically feasible.

Terminal Operating System (TOS)

Container terminal processes are not really complex as the rules for optimum flow and stacking of boxes between berth and gates are basically direct, however, it is the large number of moves and movements which sums even small process deficiencies up to large losses of productivity. As the uncertainty when boxes will be delivered and picked up on the yard does not allow for deterministic solutions, heuristics appears to be the best way to optimize processes. Within the scope of GREEN EFFORTS process capturing, mathematical modelling, simulation and visualisation was essential, providing valuable tools beneficial not only for the project but for future terminal optimization, too.

No container terminal could operate without the support of a terminal operating system (TOS) and the systems currently in use are rather mature, however, there is still room for improvement to enhance energy efficiency and hence reduce costs and emissions. The GREEN EFFORTS catalogue for improvement comprises the following items:

- Interoperability (not integration!) with container handling equipment (CHE) tracking system to minimize traveling distances of vehicles and adjust speed of operation (“operation speed kills fuel economy”) according to actual needs

- Interoperability with berth planning system to stack containers to minimize re-stacking and movement distances over the whole box stay on the yard, continuously adjusting to changes of estimated time of arrival (ETA) of vessels

- Forecast of cost of resources (container handling equipment , staff, time)

- Real-time availability of information required for decision-making and disturbance-management

- Performance analysis to learn from conducted operation to improve yard and equipment strategy (reverse engineering).

Optimization of yard operation of course depends on working rules. When e.g. there is a “gang” system per crane in place, it is not possible to send a straddle carrier or tractor where it is required most. The enhancement of TOS and the extension of interoperability with related systems usually require early involvement of job stewards and union representatives.

Standardization

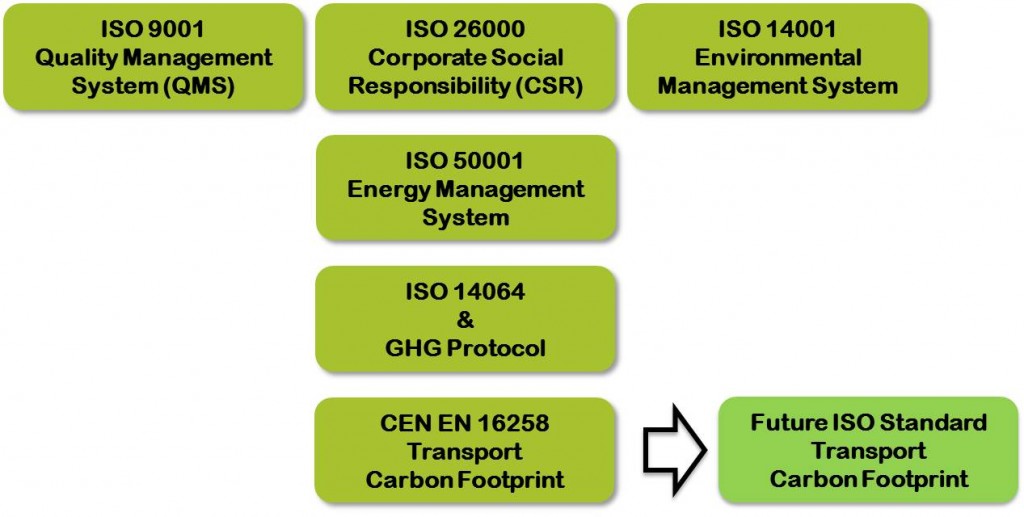

GREEN EFFORTS aims at reduction of emissions, mainly by improving energy efficiency and by exploiting regenerative energies. To measure the success of all endeavours a standardized monitoring and reporting system is required.

Energy Management and Carbon Footprint related Standards. (GREEN EFFORTS/Jens Froese)

The Greenhouse Gas Protocol (GHG Protocol) provides a useful standard to capture emissions [12] which is also the purpose of ISO 14064-1:2006 Greenhouse Gases – Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals.

Both standards aim at the total carbon footprint of a company entity. Clients of transport services increasingly ask for the carbon footprint share per unit transported to include into their capturing system. Upon this request the first standard to calculate the product-related carbon footprint in transport, CEN EN 16258, was introduced in May 2014 currently only covering carriers as trucks, railways, airplanes and ships but in a next step also aiming at transhipment and cargo distribution centres. As a preparatory action to establish a related ISO Standard, ISO/DIN launched an “International Workshop Agreement (IWA)” 8th July 2014 in Berlin. In brief the GREEN EFFORTS requirements are:

- Transparent and unambiguous applicability of standards is a core requirement

- Application must be simple and in line with other management standards as ISO 9001 (Quality Management System), ISO 26000 (Corporate Social Responsibility) and ISO 14001 (Environmental Management System)

- As emissions are a direct result from energy consumption, ISO 50001 (Energy Management System) should be part of the overall approach to manage energy consumption and reduce emissions.

Thus a combined standard system can be established to provide required data with minimum effort and maximum transparency, composed of ISO 50001 Energy Management System, GHG Protocol or ISO 14064 to capture emissions on company level and CEN EN 16258 respectively the expected follow-up ISO standard to provide the product related carbon footprint and to provide mitigation opportunities by improved energy management. This approach allows to establish a consistent data capturing and reporting system following a universal logic and resulting in minimum administrative efforts.

Hinterland Truck Traffic

Because of the potential impact on human health air quality is of serious concern in Europe [13] and ports are increasingly criticised as being one of the main sources of particulate matter (PM) emissions in port cities. This is not a carbon footprint issue but GREEN EFFORTS strongly recommends to associate PM-emissions to carbon dioxide (equivalent) emissions. This will foster capturing of emission data and combatting.

Besides the ships berthed in ports, where emissions are caused by power generation by diesel engines, trucks to and from the terminals, especially when traffic jams occur and stop-and-go traffic maximises emissions, have been identified as significant contributors to PM emissions. GREEN EFFORTS therefore searched for measurements to avoid traffic jams in ports and in port approach areas.

A simulation model was developed to identify critical traffic conditions and to serve as a traffic management tool. Constant speed, even when relatively low, ensures maximum throughput of trucks and minimum emissions. To achieve this GREEN EFFORTS recommends:

- Decoupling picking up and dropping of containers which is a cause of peak traffic because senders or receivers of boxes are only available during restricted time windows, usually coinciding with peak city traffic. Picking up containers but not having the opportunity to deliver it immediately requires guarded trailer parking areas which should also function as pre-gates. This break in the haulage process will cause additional costs but these will be compensated by the opportunity to use low traffic periods for the leg from/to the trailer parking to/from the terminals and hence increase haulage productivity.

- Slot management at terminal gates in combination with automated clearance of driver, truck and container.

- Truck traffic management whenever necessary to ensure constant speed of trucks.

Green Ports

The port industry always argues that they need each and every square meter for their operations and hence do not have land for literally greening ports by planting trees. More thorough investigations, however, usually show that there is always land in a port which is not used for logistics operations. More trees will of course not save energy but improve the relationship to the residents in the neighbourhood. Terminals do not really provide an attractive view and they generate noise and disturbing light at night. There is only a small stripe of land around a terminal required to allow the construction of a hump to plant fast-growing trees and bushes and hence provide a green shield.

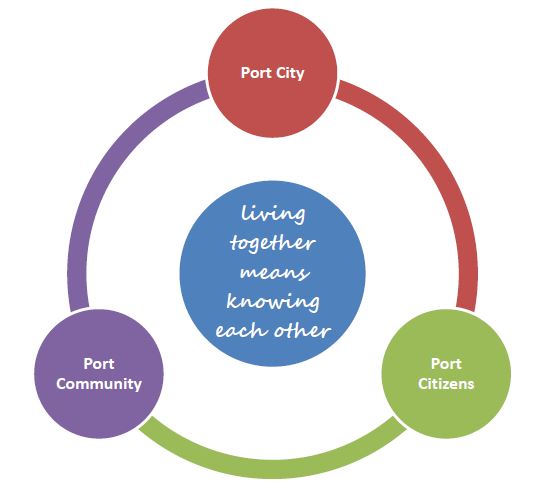

Ports are industrial areas and therefore cities usually do not think how a port could be made more attractive to those, who live around it. Airports usually have observation hills to allow the public to participate in the busy operations. Ports could also create a few pleasant areas allowing to watch the harbour life. To contribute to mitigation of carbon footprint those spots might be only accessible by walking or by bicycle, leading through green port lanes. Such spots continuously open to the public could be good amendments to activities undertaken by Port Cities [14], e.g. single events like a concert by the Symphony Orchestra of Gran Canaria at the container terminal La Luz of the port of Las Palmas or regular events like port anniversary celebrations (e.g. Hamburger Hafengeburtstag) or Port Days (e.g. Trelleborg Hamnen Dag).

The Port Center Concept. [15]

Conclusion

Detailed measurement of energy consumption is the key to identify most promising areas to apply saving measures and to exploit regenerative energies. There is no rocket science required to achieve significant savings and to exploit regenerative energies. The drivers of operational and technical innovations are cost issues but the port industry should understand that sustainability is a true shareholder value, difficult to show in the annual balance sheets but providing a payback over longer periods to be measured by residential acceptance and by simply making a port a better place to work and to live.

Notes

[1] GREEN EFFORTS website: https://www.green-efforts.eu/

[2] Wilmsmeier, Froese, Zotz, Meyer: Consumo de energía y eficiencia energética: nuevos retos del comercio con contenedores frigoríficos en las terminales de contenedores de América del Sur; Boletín FAL, Edición No 329, número 1, 2014, UN CEPAL

[3] Bergholz Werner: GREEN EFFORTS White Paper #01: Reduction of CO2 Footprints of Container Terminals by Photovoltaics, 2014

[4] Hasberg, Dania: GREEN EFFORTS White Paper #10: Wind Energy in Ports and on Terminals, 2013

[5] Hasberg, Dania: GREEN EFFORTS White Paper #11: Biogas in Ports and on Terminals, 2013

[6] Buhl, Reiner; Bahl, Alexander: GREEN EFFORTS White Paper #14: Geothermal energy and heat for ports and terminals, 2012

[7] Hardt, Claudius J.:GREEN EFFORTS White Paper #02: LED Technology for Container Terminals, 2012

[8] Tao, Liang; Guo, Hui: GREEN EFFORTS D7.3 “Smart Grid Technology for Terminals and Ports”, 2014

[9] Tao, Liang; Guo, Hui: GREEN EFFORTS D7.2 “Load Shedding for Terminals”, 2014

[10] Tao, Liang; Guo, Hui: GREEN EFFORTS D7.1 “Maximizing of Power Factor for Terminals”, 2014

[11] Kocks Crane International, Uwe Pietryga: “Trends in Efficiency for Ship-to-Shore Container Cranes”

[12] The GHG Protocol Corporate Standard, https://www.ghgprotocol.org/standards/corporate-standard

[13] European Commission: Clean Air Policy Package, December 2013

[14] The Worldwide Network of Port Cities, https://www.aivp.org/en/

[15] https://www.portcenternetwork.org/port-center-concept/

Head image: Eurogate Container Terminal Hamburg. (Photo: Michael Zapf)