╔

Since beginning of 2020, staring at the horizon from Praia Norte in Viana do Castelo, Portugal, or up in the mountains looking down to the sea, you can distinguish in the distant horizon three wind turbines floating 20 km offshore. If you are lucky enough to go at sea, and despite the days when you might feel heavy waves from the boat, you will see three structures continuing to float steadily while generating power for about 25,000 Portuguese households. This is the WindFloat Atlantic project.

Strong Winds are blowing offshore

In a context of a demanding energetic transition towards low-carbon energy, offshore wind solutions embody the ability to meet high demands in electricity and will be crucial in generating the clean energy necessary for green hydrogen production. Indeed, offshore winds are blowing strong, and in a continuous manner. Implementing windfarms at sea further from the coast and far from any kind of interference in the wind, means greater capacity of generation.

In locations where sea depths do not allow for bottom-fixed projects and to reduce environmental and visual impacts, floating wind technology is now proven to be ready for commercial scale. We are at a turning point of the technology, and this, thanks to projects like WindFloat Atlantic (WFA). In Portugal, WFA stands as a cornerstone for the industry since the beginning of 2020. It represents the learning experiences that were needed for floating offshore wind to seem feasible and ready to develop into large scale offshore wind farms. Going through the project’s history, we will present the technology, the steps of implementation and the current phase of operation & maintenance of this real innovative project, steadily floating offshore.

Floating technology and energy capacity

As mentioned, the WFA project is located along the north coast of Portugal, about 20 kilometres from Viana do Castelo, in the maritime area and within 12 miles of the Portuguese territorial sea, in an area of the Atlantic Ocean with a depth of approximately 95 meters. Windplus, S.A. is the company responsible for the development, construction and operation of the WindFloat Atlantic project, and whose current shareholders are Ocean Winds (ENGIE and EDPR joint venture dedicated to offshore wind), Repsol and Principle Power Inc. (PPI).

The offshore wind power plant holds an installed capacity of about 25 MW, and consists of 3 MHI Vestas V164 wind turbines, with a unit power of 8.4 MW, supported by 3 semi-submersible floating structures based on the “WindFloat” technology, developed by PPI. This technology is based on the evolution of the platforms used in the oil industry for its application to the offshore wind energy sector, whose technical feasibility had been demonstrated with the full-scale prototype called “Wind Float 1”, with a commercial 2 MW Vestas V80 turbine. This first project was operational 5 km along Aguçadoura, Póvoa do Varzim, for about 5 years, starting December 2011, without any relevant technical incident.

Each triangular floating platform is semi-submersible and anchored to the seabed. It consists of 3 vertical columns, interconnected/solidary to each other, and to one of them is attached the base of the wind turbine tower. The lateral distance of the platform (between the centre of the columns) is about 50m. Its stability is reinforced by a system of gates that are filled with water at the base of the three columns, associated with a static and dynamic ballast system. This active ballast system moves the water between columns to compensate for the stresses caused by the wind thrust on the wind turbine. This moving ballast compensates for significant differences in wind speed and direction. Its purpose is to keep the wind turbine tower upright to optimize its performance.

The structure is anchored to the seabed by three mooring lines, formed by conventional components: drag anchors and cable chains. Each line is connected to one of the columns.

Floater, WindFloat Atlantic. (© Ocean Winds, Lino Escuris, Abril 2022).

The challenges of implementation

The construction process began in 2018, with the fabrication of the floating platforms. Windplus contracted the manufacturing process of two of them to A. Silva Matos (ASM) and a third platform to the Navantia-Windar consortium.

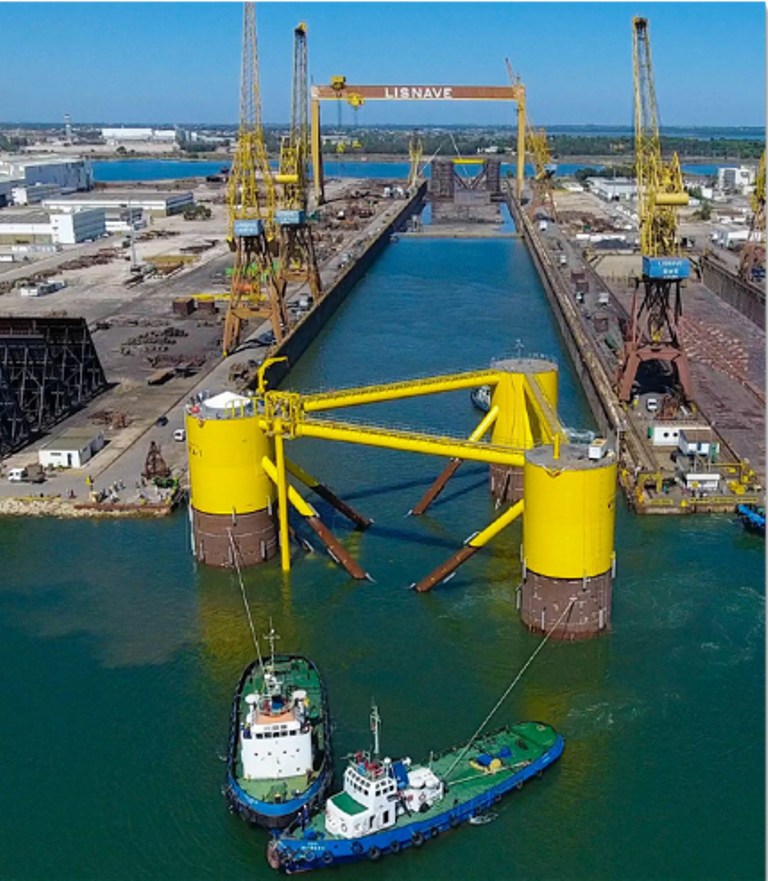

In the case of ASM, the fabrication and assembly process used a dry dock, from which the two platforms could be towed once built, using a conventional tugboat. Thus, the most important works were carried out on land, which has allowed minimizing the possible impacts derived from the assemblies at sea.

In the case of Navantia-Windar, once the structure was completed, and as there was no dry dock near the Navantia shipyard in Ferrol, the platform, once completed, was moved from the quayside to a semi-submersible vessel barge, which then sailed to deliver the platform to the outer port of Ferrol to complete the floating, ballasting and mooring operations, before installation of the wind turbine took place.

Floaters towed by tugboat from dry dock, Lisnave, WindFloat Atlantic. (© WindFloat Atlantic).

With the completion of the installation of the wind turbine on top of the platform, the transport of the platform-wind turbine assembly from Ferrol to the site of the offshore wind power plant began, when, in the meantime, Bourbon (the company in charge of all offshore installation logistics) had already placed and positioned the anchors that make up the moorings system.

Each anchor was fixed by placing it on the (sandy) seabed and pulling/dragging by use of an Anchor Handling Vessel, which causes the anchor to bury itself in the planned location. The operations to hook-up each platform-wind turbine took place afterwards, which in turn has allowed for the electrical interconnecting cable between the wind turbines to be performed by Bourbon and JDR Cables (manufacturer of the dynamic cable). While the offshore power plant was being installed, the Portuguese Transmission Operator (Redes Energéticas Nacionais, REN) installed the export static cable and build the due electrical infrastructure (switchyard) right at the landfall where the cable arrives from offshore. Only then were the platforms and wind turbines able to be commissioned to start generating electricity.

The appropriate method of cable installation was chosen based on the geological and meteorological-oceanic studies conducted prior to installation. Given the length of the cable (less than 21 km), the installation was carried out in a single campaign (using a reel boat), under REN’s contractor Heng Tong.

Installation of wind turbine, WindFloat Atlantic. (© WindFloat Atlantic).

The energy produced is transported onshore through a REN submarine power cable, whose transition to land is made at the north pier of the port of Viana do Castelo. A subway electric cable was installed from the sectioning substation – built by REN – along the public road, to connect to the National Distribution Network at the existing Monserrate Substation (60/15 kV), also in Viana do Castelo.

Sailoff from Ferrol, WindFloat Atlantic. (© Dock 90).

Successfully up & running thanks to the Viana do Castelo Port and city

Since beginning of 2020 and the completion of its installation, WFA is performing well above expectations. WFA registered high levels of availability from the start, and it reached 75 GWh in its first year of operation. The energy produced that year was enough to supply electricity to 25,000 Portuguese households and avoid the emission of 33,000 tons of CO2.

The floating platform structure has been designed and certified to remain in operation for 25 years.

WFA is being operated from the O&M based in the commercial port of Viana do Castelo. The port of Viana was also our base for the commissioning works (start-up of the turbines and floats) and the base for the WFA team in the coordination of all the offshore works in the park. Every action of maintenance needed is coordinated from the base thanks our team in Viana.

In addition, the WFA visit has become an important passage for people from the offshore wind sector in order to witness the proven technology and enjoy Viana.

WindFloat Atlantic. (© Ocean Winds, Lino Escuris, Abril 2022).

Inspiring others to go further

WFA holds three essential characteristics that differentiate it from traditional offshore wind power plants:

- It has enabled the installation of multi-MW wind turbines in locations further offshore, at depths greater than 50 meters, normally inaccessible to structures fixed to the seabed.

- Each wind turbine is operating on a floating platform that guarantees its stability and are only anchored to the seabed by chains. This system avoided the complex offshore operations associated with the installation of traditional fixed structures, thus reducing the potential impact on the environment.

- The platform and wind turbine were built and assembled entirely in onshore ports and then transported by sea to their final location. These features eliminated the need for large transport and installation vessels, with the ability to lift large loads, avoiding complex, slower and more costly operations at sea.

This success is inspiring more than one project around the world. Based on the proven technology and learnings from WFA’s experience of implementation and operation, Ocean Winds, its main shareholder, has recently reached the Final Investment Decision on its Eoliennes flottantes du golfe du Lion (EFGL) project in France. The EFGL pilot project, although similar to WFA, represents another step forward as it managed to integrate three 10 MW floating wind turbines, the most powerful ever installed on a float, and reach 30 MW total capacity. As the third generation of the Principle Power Inc. floater technology – after WindFloat 1 (2MW) starting operation ten years ago and WindFloat Atlantic (25MW) from two years ago – the design of the EFGL floater holds significant improvements and new solutions. With such a long operational experience, it is now the most advanced floater technology and is ready for a full-scale commercial deployment.

These pilot projects are just the beginning as Ocean Winds recently secured exclusivity development rights for KF Wind, a 1.2 GW floating offshore wind project in Ulsan, South Korea, on its way of being the world’s first large scale commercial floating wind project. Ocean Winds is actively developing further opportunities for commercial floating projects under the responsibility of the Southern Europe Business Unit, supporting the energy transition plan and bringing a great economic opportunity for the countries which embrace this new vector of the renewable energies.

The future of energy just started floating.

HEAD IMAGE | WindFloat Atlantic. (© Ocean Winds, Lino Escuris, Abril 2022).

╝

References

Proyecto Windfloat Atlantic (septiembre 2019), Cuadernos de energía, 60 edn, Club Español de la Energía.