Port generations

Beginning as a first generation cargo port, the Port of Rotterdam has developed through several generations of innovations [1] by adding logistics services (2nd), connecting to supply chains through production and distribution (3rd) and creating modern information systems linking it to other ports and its hinterland (4th). Today, it is a typical 5th generation port – a dynamic and user-centric community port that has strong interfaces with local industry, from goods processing and logistics services to maritime production. The port is now looking forward to becoming a 6th generation port – a development taking place in a context of automation and integration in the global logistics system, known as the Physical Internet. Next to its economic development, the port has embraced the objectives of environmental and social sustainability as innovation challenges.

Here, we address these key innovation stages of the past decades and highlight organizational factors that have made these developments possible.

A key innovation that kick-started Rotterdam’s strong position as a European container hub was when it introduced the first fully automated container terminal in the world, with automated guided vehicles and automated stacking cranes. This was opened in 1993, at a time when the trade in manufactured goods between the far East and Europe was accelerating. Around this time, Rotterdam became the largest container port in the world and main gateway to Europe for manufactured and fresh produce.

Next to the terminal activities, hinterland modes have known their share of innovations. The Rotterdam port authority supports individual modes of hinterland transport through dedicated policies for road transport (the Container Exchange Route – an internal connection between the 5 main deep sea terminals); rail (the dedicated rail freight Betuweline, a 5-billion Euro investment, opened in 2007) and inland waterways (the Nextlogic information system supporting coordinated planning of terminal visits). Because of the dense road and river system in the immediate hinterland of the port, there are more than 30 inland terminals in an area of around 100 x 100 km2. Together, these function similarly to a city’s subway system with dense schedules, allowing the port to optimize container movements across modes and synchronizing different modes around terminals and destinations. This system, known as “synchromodality,” was pioneered by the ECT terminal in the port of Rotterdam.

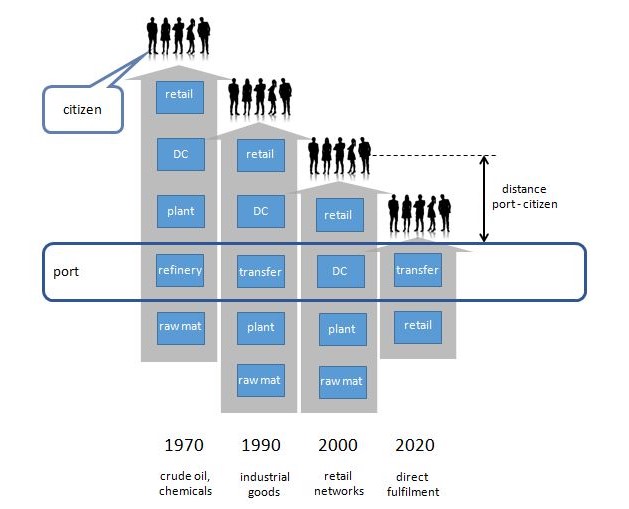

Improvement in cargo transport services has also spurred the development of Rotterdam as a logistics and supply chain port, including the establishment of European, national and regional distribution centres in the Netherlands. We have seen almost a doubling of warehouse capacity in the last 20 years. Rotterdam has thus evolved into a true supply chain port, supporting the heartland of the Dutch manufacturing industry in the 200 km long South-West corridor towards Venlo and the German Ruhr area.

Rotterdam’s customer centricity has been a gradual evolution, with an increasing emphasis on consumer-ready products and shipping bypassing European wholesalers or retailers through direct sales and shipment to consumers by global Internet platforms like AliExpress. The port has never been as close to the citizen as today.

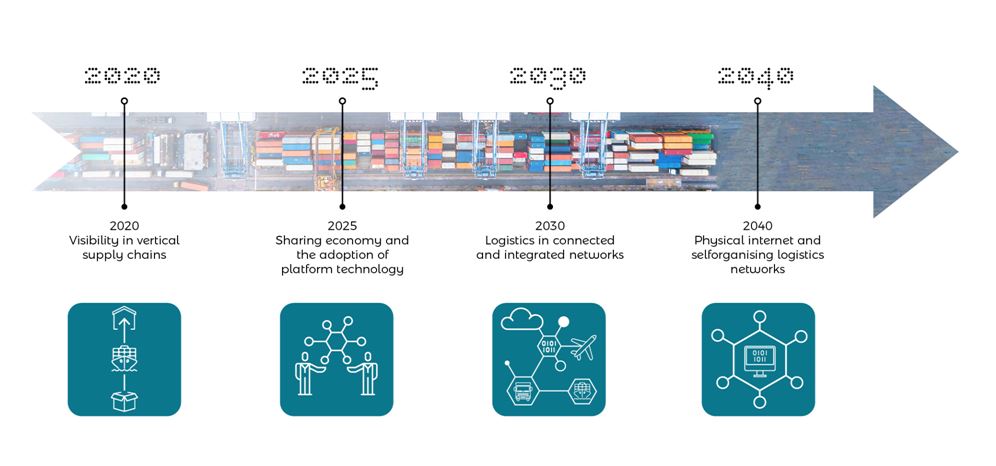

As with consumer product platforms, information systems for trade and transport are also developing fast. Modernization of information services is key for a fast turnaround of ships. European ports offer a “single window” interface for arriving ships, a clear entry point for all obligatory information services that surround the port call, like arrival registration, bunkering requests and, in Rotterdam, customs. Once fully operational and harmonized across Europe, the time spent on administering port calls should be cut by 50%. Recent innovation projects like the EU project CORE were looking into the possibility of creating data pipelines for customs at global level. For the logistics services industry, digitalization of services and the platform economy mark the start of the new wave of development of the port towards a Physical Internet port. Together with the automation of transport management and execution, this will support the development of the port towards an autonomous or self-organizing system.

Port futures

The Physical Internet (PI) is a vision for the long-term development of the global logistic system as an open web with fully standardized assets where freight movements are continuously optimized in a coordinated fashion [2]. The PI vision describes how many seemingly independent innovations in the freight logistics systems can work together productively. Due to the major efficiency jump created by the system, it will exert less pressure on the environment. And because of the open collaboration between networks, the freight system should also become more resilient. Recently, a group of experts developed a roadmap [3] for the future evolution of transport networks in the PI. It includes 5 main lines of alignment for all stakeholders, which will give direction to future port innovation:

- Services: from separated subnetworks of services of individual service providers, modes and regions, towards one integrated global service network

- Access: from the current situation of protectionism and constrained pooling of resources towards open sharing of assets and free access to the network

- Governance: from a mixed bag of regulations, trade terms and non-standardized agreements towards harmonized arrangements across modes of transport

- Networks: from mode-based services to fully autonomous synchromodal transport networks

- Freight hubs: from the current focus on container level physical services towards autonomous, shipment-level administration and handling of cargo.

These lines of development will allow the Port of Rotterdam to develop its capabilities to grow inside the PI, connecting to other hubs and integrate its services more deeply into supply chains. Research is ongoing to map these developments and formulate strategy recommendations for the port [4].

Head Image | Thialf Heerema location Calandkanaal. (© Kees Torn; Source: Port of Rotterdam Authority, 2020).

Notes

[1] Lee & Lam (2016). Developing the fifth generation ports model. Palgrave Macmillan, London.

[2] Montreuil (2011): The Physical Internet Manifesto.

[3] ALICE (2021): Physical Internet Roadmap, etp-logistics.eu.

[4] Fahim, P., et al. (2021). The Physical Internet and Maritime Ports: Ready for the Future. IEEE Engineering Management Review.